Project news Proteins from seaweed and legume residual flows

A sustainable and affordable solution for the recovery of biofunctional and technological proteins. That is the goal of European project ALEHOOP, with ILVO as one of the 16 partners. This project foresees a pilot-scale demonstration aimed at the extraction of low-cost food proteins by means of a sustainable and low-cost process, based on residual flows of macroalgae and legumes. The purified proteins will be used in the food and feed industries.

Alternative protein sources

In the food and feed sector, consumers are demanding functional and affordable natural proteins from sources other than conventional ones. In addition, the industry demands protein formulations of biological origin, which can be produced at low cost and lower environmental impact. The ALEHOOP project offers a sustainable and low-cost solution for the recovery of biofunctional and technological proteins. The current sources of these proteins are soy, cereals or potatoes (mainly imported in Europe and ecologically unsustainable). The scarcity of this type of resource in Europe, whose availability does not meet the demand of the region, forces the search for new sources of proteins, which have not been exploited so far.

Processing residual flows and increasing protein harvest

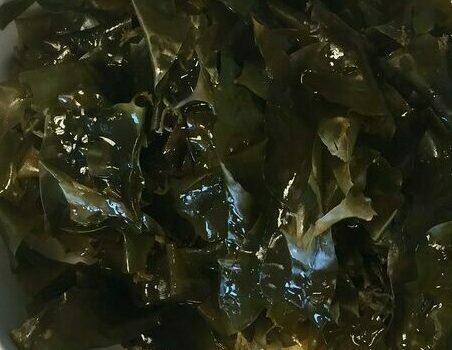

In this project, the main objectives are; (1) to take advantage of the by-products of processing materials of plant origin (legumes) and residual macroalgae as feedstock, which can provide the requested proteins in a more environmentally friendly way. Green and brown macroalgae are collected in Rias Baixas (Spain) and Norway, respectively. The residues after the processing of legumes will be collected from Spain. Both raw materials will be sourced from the region, which will stimulate the local economy and has the potential to reduce imports of currently used raw materials; (2) optimizing the processing of algal biomass through biorefinery, in order to increase protein harvest over other laboratory-scale processes, taking into account quality and quantity. It is assumed that the protein purity of these treatments is 60-70%.

Reduced environmental impact and lower costs

Both the optimization of the process and the valorization of the plant waste will lead to a significant reduction of the CO2 footprint compared to conventional processes (30% less), as well as significant energy savings in an order of magnitude of 20%. Production costs will also be reduced by about 20% compared to conventional processes. The project will lead to the development of two new products, one based on seaweed (macroalgae) and one based on legumes.

Project: ALEHOOP

Term: 2020 – 2024

Funding: Horizon H2020- research and innovation fund of the European Union, call H2020-BBI-JTI-2019.

Partners: 16 partners from 6 countries; Spanish CONTACTICA S.L. coordinates.