Research project Small-scale innovative food processing equipment

General introduction

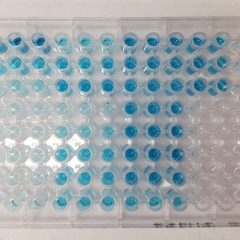

Food-related protein research requires specific equipment. Several technical gaps have been resolved within the INNOLAB project. In terms of machinery, the Food Pilot at ILVO in Melle is well equipped with very versatile equipment to be able to simulate most food operations at pilot scale, including extraction of (new) proteins. When the resulting protein extractions do not yield large amounts of protein, pilot-scale processing experiments cannot be performed. In other cases, new alternative sources of protein in the exploratory phase of primary production are also only available in very small quantities for further testing and analysis. To meet the demand from specialized SMEs, investments and initial tests have been made in a separate room with innovative small-scale commercial equipment. Very small amounts (0.5 kg to 5 kg) of protein-rich raw materials can now be tested and studied with innovative technologies.

Research approach

This project enabled the investment in small-scale equipment for cutting, grinding, separation, drying, heating and shaping of protein-rich raw materials. The steps before protein extraction require equipment for the pre-treatment of the raw materials, while the steps after extraction lead to product developments. The project also included the adaptation of a space housing these devices.

Relevance/Valorization

In combination with the other pilot devices in the Food Pilot, complete processing processes can be simulated from various protein-rich raw materials to new end products in the fruit and vegetables, meat, bakery, dairy, ready meals, and the like. This unique test environment serves Flanders as well as international companies. Up to 550 pilot tests are carried out annually in the Food Pilot, which our customers successfully transform into tangible realizations. This project was done in partnership between ILVO and Flanders'FOOD, and was financially supported bij EFRO and the Province of East-Flanders.