Dossier Allergens

Due to the lack of an effective remedy for patients with food allergy, the correct labeling of food products is extremely important. In order to control this labeling and to detect cross-contamination with food allergens during the production of food products, ILVO is strongly committed to reliable detection and accurate quantification of these allergens.

New robust detection method

What does ILVO do?

-

Allergen testing for the FASFC, among others. ILVO is NRL: services to FASFC and accredited labs. Also active partner ENFADL network.

-

Development and implementation of innovative technologies for simultaneous detection of different (processed) allergens.

Development and implementation of innovative technologies for simultaneous detection of different (processed) allergens. -

Creation of test materials containing food allergens under realistic production conditions through the Food Pilot.

-

ILVO investigates the influence of food processing on both allergen detection and allergenicity, and strives for harmonization.

ILVO investigates the influence of food processing on both allergen detection and allergenicity, and strives for harmonization.

What does the law say about allergens and labeling?

Food allergies, due to both the increasing number of individuals with food allergies and the severity and frequency of symptoms, are a growing health problem within our society. As there is currently no effective remedy available, patients can only protect themselves preventively by completely avoiding the consumption of the ingredients they are allergic to. To help consumers with this, the European Union requires the clear labeling (e.g., fat, underlined) of 14 allergens (Regulation (EU) No. 1169/2011) on the label when used as an ingredient. For non-prepackaged foods, this information should be available upon request. But these allergens can also be accidentally present in food products through cross-contamination or contaminated raw materials. Control of the labeling as well as control of such accidental presence is therefore important to protect the consumer.

Which techniques can be used to detect allergens?

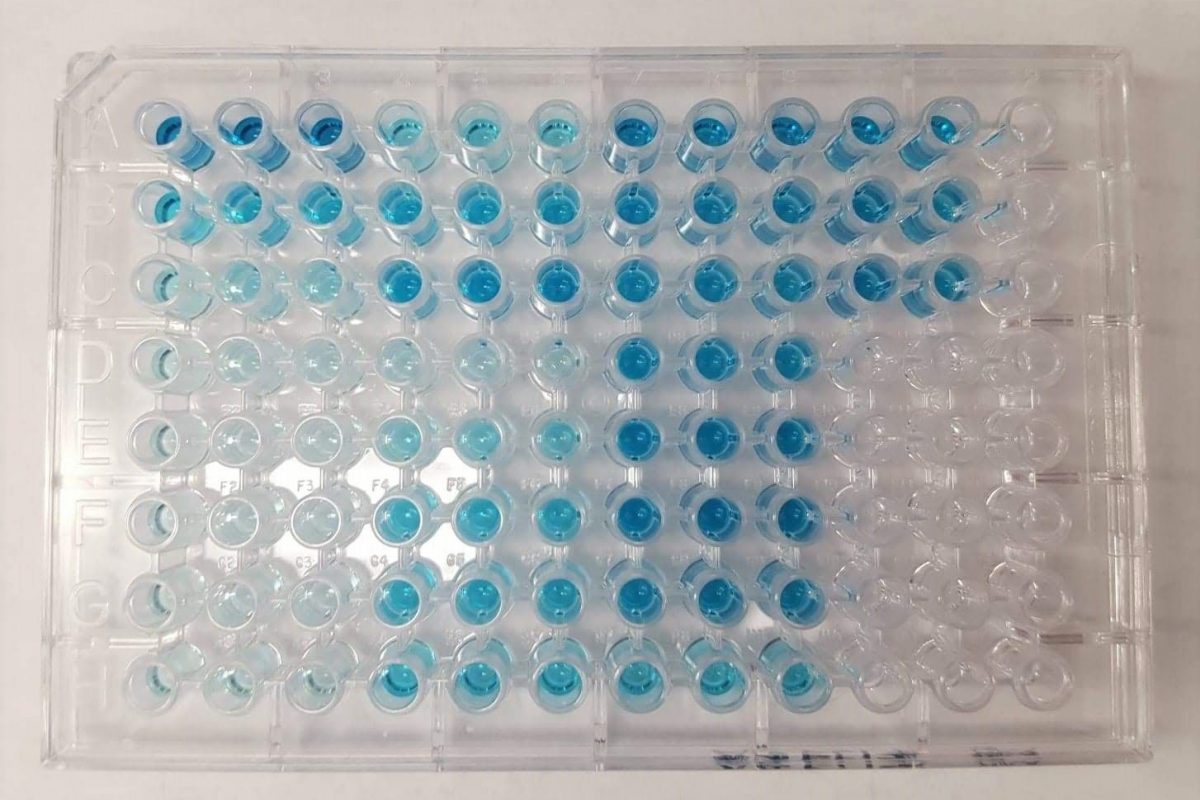

Despite the mention of "allergenic ingredients" in the EU regulations, none of the detection methods used is able to measure the ingredient itself. For example, no technique (ELISA, PCR or LC-MS/MS) can directly measure the presence of, for instance, peanut in a food product, but they detect a specific marker. ELISA measures the presence of one specific protein, PCR searches for specific DNA, and LC-MS/MS detects and quantifies a specific peptide obtained after degradation of a specific protein with trypsin. In order to be able to compare the results of these different techniques and to check whether allergenic thresholds have been exceeded, all results obtained must be expressed in total mg of allergenic protein/kg of food product.

How does food processing affect allergens?

Most of the food products we purchase and consume have undergone some form of processing. This can range from simply heating ingredients to destroy dangerous microorganisms (e.g. pasteurization of milk) to complex processing procedures where a variety of ingredients are mixed and processed into a final product such as a cookie. That processing can have a major impact on the various components of the allergenic ingredient such as DNA and proteins. Since these are the target analytes used in detection and quantification of food allergens, processing also has an impact on the effectiveness of the detection method used to detect (traces of) allergens in food. But also the epitopes, those particles of the allergen to which the immune system responds, can be affected by processing, and this can result in both products with reduced allergenicity, and products with increased allergenicity.

ILVO allergen research

Routine analyses

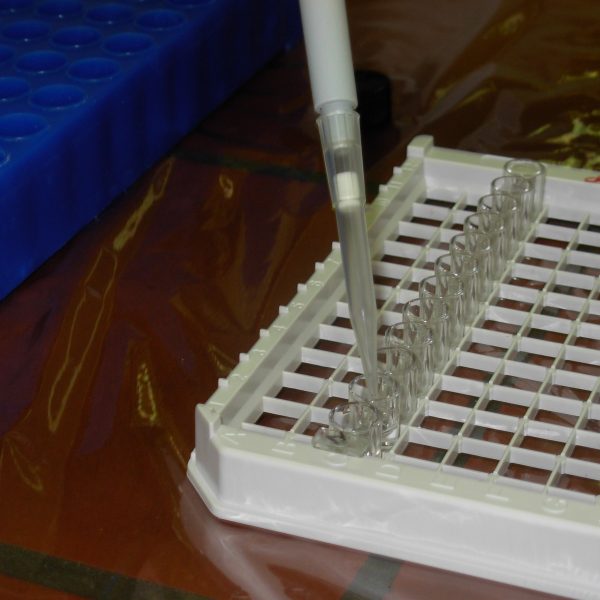

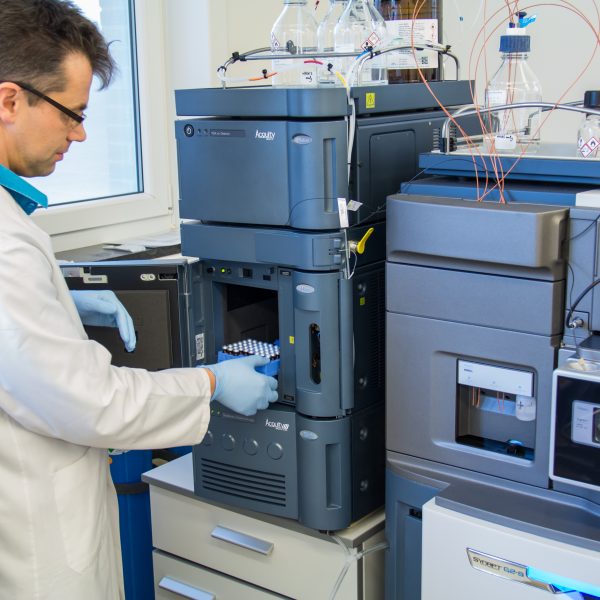

The control of food for both declared (labeling) and hidden (cross-contamination) allergens is an important task to protect allergic consumers. As a routine lab, ILVO carries out classical ELISA and qPCR tests for the FASFC and food companies, among others. In addition, within the reference activities (ILVO is a partner of the Belgian National Reference Laboratory for allergens, NRL-ALLERGEN and of the ENFADL network) but also within project activities, the development, optimization and validation of new methods and technologies are highly valued. LC-MS/MS detection is particularly interesting to be able to detect multiple allergens simultaneously, independent of any processing that the matrix underwent. Digital droplet PCR (ddPCR) has numerous applications for, among others, determining the identity of fish, GMO detection and quantification. This PCR-based technology has specific advantages in terms of sensitivity and is less dependent on inhibiting factors from the food matrix.

Harmonization & conversion factors

In order to compare the results obtained with different techniques (ELISA, PCR, LC-MS/MS), all results must be expressed in total mg of allergenic protein per kg of food product. However, no technique measures this unit. Therefore, to make conversion possible, a specific conversion factor is needed for each of these techniques (and for each technique for each analysis). ILVO is involved in the determination of these conversion factors and in the harmonization of detection methods both from its own research and from international research projects and the European Network of Food Allergen Detection Laboratories (ENFADL).

Production of test materials

When detection methods for allergens were being developed, an extract of the substance to be detected was often added to the food product and then tested. However, the detection of allergens can be strongly influenced by processing techniques. It is therefore important when developing and validating new detection methods (e.g. ddPCR, LC-MS/MS) that the allergen undergoes the same processing steps as industrial products. This is the only way to obtain representative test material, which can then be used to study the impact of (innovative) processing on allergenicity. With the Food Pilot, ILVO has the possibilities to produce such test materials with the help of the available expertise and semi-industrial processing equipment.

Contact an expert

Research projects