Press release Livestock housing with renewable energy and combi cooling systems?

Research from COOLPIGS, COOLCHICKS (2x Vlaio) and RES4LIVE (H2020) show the way

Heating and cooling of livestock housing will soon require less than half the fossil fuels using on-farm produced renewable solutions. Even during periods of high energy demand. Today this is a rarity. Cooling in particular is becoming increasingly important as the number of hot days increases.

Successful experiments from the Vlaio projects Coolpigs and Coolchicks show that high-pressure water misting reduces the inside temperature in a fattening pig house by an additional 2.5 °C. In broiler houses, morning-started cooling via nebulizers, ventilation and pad cooling drops the temperature by 4 °C on 30 °C days. A pilot setup (of the H2020 RES4LIVE) with solar panels, heat pump and thermal tank, and LEDs in the test barn Varkenscampus (ILVO, UGent and HoGent te Melle) appears to cover most of the barn's energy needs while emitting nearly half the greenhouse gases.During the COOL ENERGY EVENT (June 18, 2024), part of ILVO's fourth AGRITECHday, the latest findings and techniques for energy generation and storage and for cooling systems were presented.

Heat stress in pigs and poultry - and energy

Both pigs and poultry are sensitive to heat, due to their lack of sweat glands and high metabolic heat production. To lose heat, both species will modify their behavior by panting, drinking more and eating less. When these efforts are insufficient, we speak of heat stress.

With summer approaching, heat stress is once again becoming a hot topic. To ensure animal welfare and avoid unnecessary mortality, it is important to give the indoor climate of the barn a lower target temperature than the outdoor temperatures.

In the COOLPIGS project, Lotte De Prekel & Alice Van den Broeke investigated the impact of high-pressure misting combined with fans on finishing pigs and farrowing sows.

In the COOLCHICKS project, Renée De Baets studied in a broiler house how the house climate can be effectively optimized via atomization, via an earlier morning start-up of the cooling system and via the relatively new principle of pad cooling.

In addition, in light of the climate crisis, it is relevant to also approach these techniques from an ecological standpoint. In the RES4LIVE project, Manon Everaert explores sustainable energy sources and installations that can reduce the use of fossil fuels.

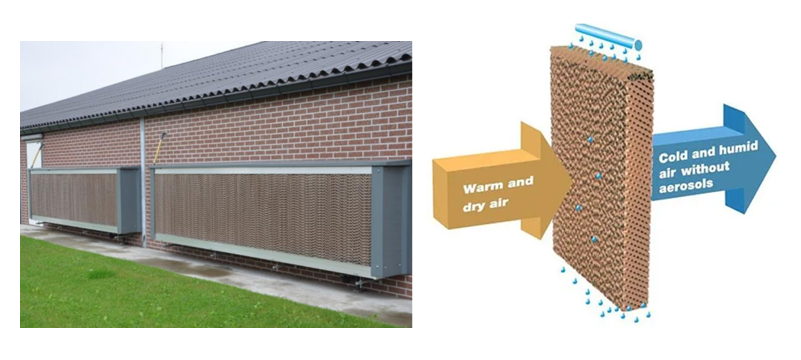

Pad cooling

Pad cooling consists of a wetted plastic package placed on the outside of the barn, in front of the air intake. The incoming air passes through a wetted package. Some of the water will evaporate. This evaporation removes heat from the air, so the air entering the barn will be cooler.

COOLPIGS (running until early 2025)

A proper balance in atomization and increased air velocity can reduce the barn temperature by 2°C.With high-pressure atomization, very fine droplets are produced using adapted nozzles and a mist is spread over the pig house compartment. In this way, the water is optimally evaporated, whereby energy is extracted from the environment. On a hot day of 32°C, the indoor temperature in a fattening pig house could thus be kept stable at about 27.6°C, the set temperature of the misting system. When comparing a control compartment without misting with a compartment with misting, a cooling effect of up to 2.5°C was observed.

However, higher relative humidity results in a greater heat load. During atomization, it is therefore essential to find a perfect balance between decreasing temperature and increasing humidity. This is easily done through the Temperature-Humidity Index (THI), a combination of relative humidity and temperature that provides a measure of potential heat stress.

Axial fans can also make a difference in barn climate. The temperature in a farrowing house equipped with such fans decreased by 2°C compared to the control compartment without fans. In addition, the THI could be reduced by 1.7 with additional ventilation.

COOLCHICKS

Nebulization and pad cooling appear to be efficient systems in a poultry house, but especially the timely start-up is important.In the VLAIO-LA project COOLCHICKS (running until the end of 2025), the effect of high-pressure misting and pad cooling on the barn climate was studied. In both systems, heat is extracted from the air by evaporating water. The cooling effect is highly dependent on the sizing and placement of the system. With the most optimal choices, it was found to be possible to cool the poultry house efficiently. On days with an outside temperature of 30°C, atomization, combined with ventilation, was able to keep the house as much as 4°C cooler than a house with ventilation alone. Both pad cooling and fogging succeeded in reducing the house temperature by up to 2°C compared to the outside temperature. Performance loss in broilers was minimized and stress in the house was reduced, increasing animal welfare.

An additional decrease in house temperature was found to be possible by starting the cooling systems in a timely manner (earlier). This was especially noticeable on warm, but not extremely hot days. As with pigs, it is also important to monitor relative humidity in poultry. After all, it is the combination of temperature and relative humidity (THI) that provides a measure of potential heat stress. In addition, 60 poultry farmers were surveyed through in-depth interviews conducted in collaboration with Pehestat. They provide an overall picture of the measures commonly used in practice, and their satisfaction with them.

Renewable energy in livestock production

Just under 8% of greenhouse gas emissions in intensive livestock production are due to energy use in the barn. Electricity use serves mainly to drive fans in the barn, but feed motors and drinking water pumps also provide a high base load. For dairy farmers, milk robots and milk cooling systems are added to this. On the other hand, mainly for pigs and chickens, heat demand is high. These types of livestock are often in closed stalls, where ventilation is crucial to create a livable environment. Only this way, a lot of heat is also lost.

According to the FAO, only 4% of energy in the livestock sector is currently provided from renewable energy sources, in stark contrast to 30% for the global energy supply.

RES4LIVE seeks renewable energy sources

The RES4LIVE project (Horizon 2020) seeks to reduce the energy demand in livestock houses on the one hand. This can be done, for example, by equipping the stables with LED lighting and a smart control system for ventilation. Where necessary, additional insulation was installed in the RES4LIVE pilot barns. On the other hand, efforts were made to use renewable energy sources. Specifically, at the pig campus in Melle (a research stable of ILVO, UGent and HoGent), 24 PVT panels were installed (a 2-in-1 PV panel and solar collector) in combination with a thermal storage tank of 800 liters, and a 2-in-1 heat pump of 25 and 40 kW.

A simulation by UGent shows that over a period of 20 years this installation costs as much as a classic gas boiler (incl. installation, maintenance, and operational costs), but can reduce greenhouse gases up to 47%. However, the investment cost is 8 times higher.The RES4LIVE project runs until October 2024, by which time the actual figures and results of the installations will be known.