Press release Good news for the bioeconomy: extracting chitin from shrimp and crab shells can be done through "soft" biological processes. The by-products also show potential.

"With enzymes and bacterial fermentation, it is equally possible to extract chitin, a useful substance, from shrimp shells and crab shells than with more aggressive chemistry-based processes," says ILVO-UGent researcher Yang Zou at the end of his PhD. This is good news for the new but growing bioeconomy sector as well as the producers of chitin, a substance used in the production of bio-plastics and additives for cultivation substrates, among other things. Moreover, the by-products of these more sustainable extraction processes also appear to have interesting properties for the bioeconomy, such as the potential to neutralize free radicals, kill nematodes and inhibit the formation of biofilms. "In any case, this research is certainly promising," say promoters Johan Robbens (ILVO) and Katleen Raes (UGent).

Processing line exists but is chemistry-based

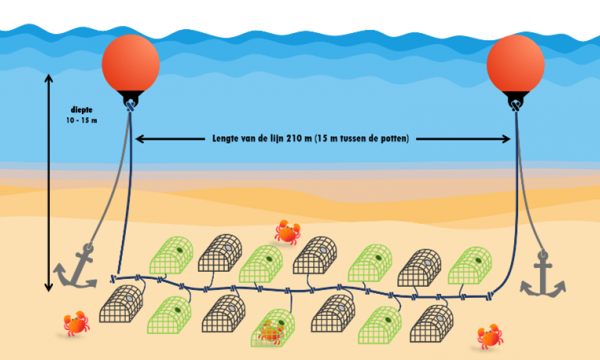

Crustaceans such as shrimp, crabs and lobsters are very valuable, both economically and nutritionally. The consumer pays a good price for them, and they are healthy to eat. We are talking about the tasty shellfish meat, of course, but the remaining parts of the shellfish also contain useful substances, such as proteins, chitin and carotenoids. Often, however, these leftovers are not processed at all. Recently, however, a trend has emerged within the circular bioeconomy and zero-waste to upgrade all residual flows. In a conventional processing, these residual flows are usually upgraded, for example, to animal feed and components for cosmetics and medical products. But up to now this has mainly been done via chemical processes, for which large volumes of solvents are required. The chemicals used often have undesirable effects on the physicochemical properties of the intended products. In order to optimize the refining of useful substances from shellfish residues, there is a need for "softer" biological processing methods. ILVO-UGent researcher Yang Zou therefore performed experiments with enzymatic hydrolysis and bacterial fermentation. He succeeded in producing press cakes of chitin from the residual flows on a laboratory scale, while retaining the desired properties. This chitin can be used in subsequent processes for the production of bio-plastics, additives for cultivation substrates and much more.

Biologically transforming crab shells into stable raw materials, with (new) potential for the bioeconomy

Based on literature data, the researcher selected several commercial enzymes that can break down shrimp shells and crab shells into their components by hydrolysis. From these tests, a protease emerged as a promising enzyme. The action of this enzyme was further optimized by adjusting the conditions for hydrolysis based on the statistical method response surface methodology (RSM). Under these conditions, two fractions could be generated, including a chitin-rich press cake. The latter showed interesting properties, indicating good processability.

In addition to experiments with enzymes, fermentation tests were also conducted. A total of 92 strains of marine bacteria were screened for proteolysis, of which 20 were retained for testing with chitin substrates. In the end, Pseudalteromonas bacteria were found to perform best. Again, two fractions were obtained. The chitin-rich press cakes again showed factors indicating good processability, with clear differences between the different bacterial strains. But the second fraction also proved to be particularly interesting here: screening of the properties showed that some of the substances obtained could neutralize free radicals, kill nematodes and prevent the formation of biofilms. These are properties that can potentially be used in crop protection and food production, among other things.

Shrimp shells: similar treatment, slightly different results

Yang Zou subjected shrimp shells to the same process of treatment and analysis. Again, different fractions were obtained: a protein-rich fraction, a wet fraction rich in carotenoids, and a chitin-rich press cake. The main product, the chitin press cake, again turned out to score well in terms of properties, especially when enzymatically treated with two commercial proteases. But the other fractions again proved to be particularly interesting, with, for example, high levels of carotenoids after enzymatic treatment, and high antioxidant activity after fermentation. Possible applications for these can be found in the pharmaceutical and food industries, among others.

Potential for further development

This research shows that biological processing techniques are very promising for the extraction of chitin. Further research should therefore focus on upscaling and a more thorough comparison with chemical techniques, not only in terms of environmental impact but also in terms of cost and efficiency, and the integration of the biological press cake into the valorization chain.

But also the by-products of the biological processes deserve more attention, especially in light of the interesting properties that were observed. UGent promoter Katleen Raes: "This research has already made a start on tracing - using chromatography - the bioactive processed substances that are responsible for eliminating free radicals, killing nematodes and inhibiting biofilm formation, but there is still a lot of work to be done there. Also, the effects of the different processing techniques on these properties need to be further investigated, so that in the future it will be possible to direct more towards the formation of a certain bioactive substance."

ILVO promoter Johan Robbens sees in the research results a confirmation of the possibilities of bioeconomy and blue biotechnology (the branch of industry that focuses on harvesting useful substances from the sea): "In terms of bioactive substances, the sea is still largely virgin territory, but blue biotechnology is making great strides. It is important, however, that extraction can take place in a sustainable manner, with respect for the environment and with the aim of closing cycles as much as possible. Moreover, we want to extract several substances from one side stream by means of cascading. With this research, Yang Zou has taken an important step in that direction."

This research was performed in the framework of the BlueShell project, funded by the Era-Net Marine Biotechnology.