In the media ILVO builds a Poultry Innovation Center

ILVO has started the construction of a new Poultry Innovation Center in Merelbeke-Melle, which will be energy flexible and climate neutral. Flemish Minister of Environment and Agriculture Jo Brouns officially laid the foundation stone for the building on May 9, together with several local representatives.

According to the ILVO, the fact that this research building is energy-flexible and climate-neutral is a first and at the same time a major challenge, because poultry housing places very high demands on variable ventilation and variable heating. This translates into peaks and troughs in energy consumption. If everything goes according to plan, the new building will open early next year.The first seeds for this Poultry Innovation Center were already planted 10 years ago. The preparations took some 5 years. The permit procedure had to be redone due to the introduction of the nitrogen decree.

Heating and cooling

The new building replaces 6 old energy-intensive, non-ammonia-emitting test houses that were demolished. The desired temperature and ventilation demand in a poultry house, including in a pilot accommodation for poultry research, are far from constant. Day-old chicks require a warm environment (32 °C with floor heat between 28 and 30 °C and relative humidity between 40% and 65%). (Almost) slaughter-aged chickens give off a lot of heat and, on the contrary, require cooling to ideally 18 °C, and thus strong ventilation.

Anyone who also wants to make such a system climate-neutral must focus on performance control of ingeniously integrated energy technologies. Climate change has increased the challenge for heating, cooling and ventilation in the livestock industry in recent years. There are more and more days with more extreme conditions regarding heat, cold or humidity.Energy flexible

Energy transition (switching from gas or oil to electricity) and recent technologies, such as data centers, are increasing pressure on the power grid. Companies and project developers are requesting increases in their existing connections or additional connections. If all power consumers and businesses effectively use their allocated capacity at the same time, then grid congestion or grid saturation can occur locally. Electricity prices in the day ahead market already take this into account: electricity prices are typically much higher in the morning between 7 and 9 a.m. and in the evening between 5 and 8 p.m. than in the afternoon, often up to double on sunny days.

Energy flexibility (on the demand side) means that (large) consumers can match their desired consumption to supply (solar) and to the transfer capacity of, for example, the entire ILVO site via modulation and via their own renewable energy sources and buffers.To deliver the intended energy flexibility and overall climate neutrality, the innovation in ILVO's new Poultry Innovation Center is mainly the combinability of renewable technologies.

Develop, test and validate

For the concept, ILVO could count on guidance and support (also financial) from the Program Innovative Public Procurement (PIO) at the Flemish Agency for Innovation and Entrepreneurship (Vlaio). PIO helps the Flemish government and Flemish public sector - through government contracts - to have innovative solutions developed, tested and validated for which there are no ready-made solutions on the market yet.

"This project is a perfect illustration of how the pursuit of sustainability and climate neutrality goes hand in hand with innovation and leads to future-proof solutions. I am pleased that we can contribute to this poultry research facility and hope that - once realized - it will act as an example for the whole sector," said Mark Andries, Administrator General of VLAIO."In the planning phase of this pilot building, we worked hard on the economics of the various technologies. The system will continuously evaluate the right (most economical, most rational) priorities in the range of sustainable heating, cooling and ventilation technologies available. This pragmatism will certainly interest the sector, and also the government," says Joris Relaes, administrator general of ILVO.

Hybrid solar panels

The building has 3 heat sources. The first is geothermal. Depth boreholes are drilled next to the building that bring heat to the surface from underground via a medium at a fairly constant temperature. The second heat source is thermal energy: photovoltaic-thermal panels (PVT or hybrid solar panels) on the roof. The third heat source is residual heat from ventilation air recovered from the chemical air scrubber.

Heating in the barn is done differently according to the needs. This is done either via floor heating (very energy-efficiently generated basic heat), or via twin pipes on the side walls. These are metal hot water pipes with a flat metal profile on 2 sides. Thirdly, the ventilation air entering the barn is cooled or heated via air groups with heating and cooling elements.Thorough insulation

Of course, thorough insulation and airtightness are important elements in making the building more inert (n.v.d.r. less responsive to heat or cold from outside). Both floor and walls as well as roof and floor are given a thick "coat". Daylight enters the rooms through so-called solar tubes.

In terms of electricity, the building does self-production. A considerable amount is supplied by PVT panels (>250 kWp). The building has no battery for storing electricity. Thermal energy storage is done through water. There is a water buffer of 50 m³ to smoothen or postpone peaks of energy production to the most favorable moments. Green electricity - to the extent that it is needed - is purchased through the Flemish Energy Company VEB and is taken from the grid.Not energy-autonomous

"On an annual basis with this building, ILVO strives for as much self-consumption of its own generated energy as possible. We are not completely energy-autonomous. That would be too expensive and is not necessary to achieve climate neutrality. It is especially important that we can deal flexibly with electricity peaks and that in this way we do not place an additional burden on the electricity grid. No fossil fuel is used in the building," says Joris Relaes.

"The decision relies on weather and building model forecasts, availability of self-generated electricity, grid prices or avoidance of grid peaks. We emphasize that with this flexible steering, ILVO contributes significantly to the energy transition in Flanders," said Gerlinde De Vogeleer, energy coordinator at ILVO.

Learning opportunities for the poultry industry.

An energy management system controls the desired energy with all techniques integrated in a network. The system automatically chooses the best (combination of) energy and heat sources. It is precisely in this control that ILVO believes there are many learning opportunities for poultry farming: how can the heat and ventilation needs of chickens during all their life phases be met with heat emission (as much as possible) at low temperature and with an accurately tuned set of priorities?

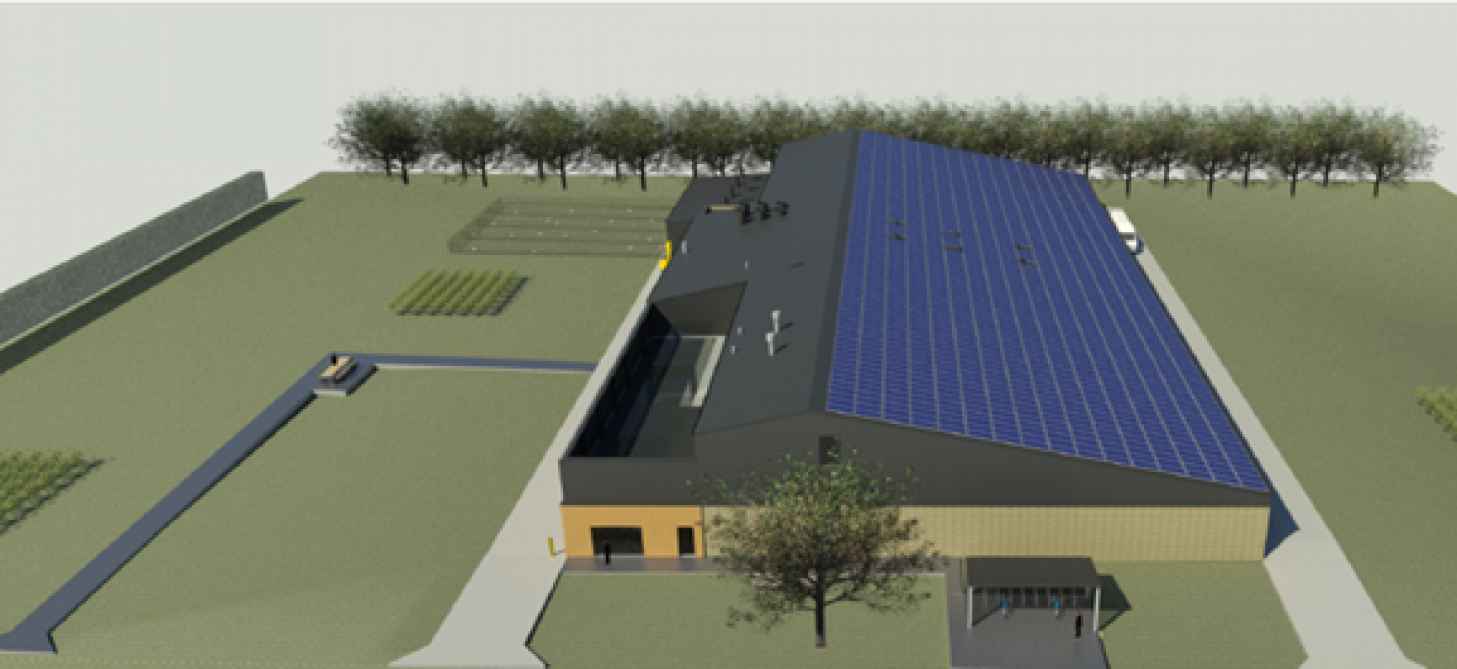

The new poultry testing facility at Burgemeester Van Gansberghelaan 92 in Merelbeke-Melle will be 70 m long and 41 m wide, and is licensed for up to 14,000 broilers. The building includes 9 compartments for a maximum of 2,000 animals each in 24 pens, in which light and climate can be accurately and separately regulated. Each compartment can house broilers or turkeys in subdivided pens, with modular or removable walls. In scientific experiments, this is necessary to draw reliable conclusions via sufficient replication.Vary with lighting

Each compartment has its own hygiene sluice, its own air shaft, its own climate control, its own feed control (automatic or manual) and separate air extraction. To facilitate administration and controls, work will be done according to the all in/all out principle, with chicks being received or discharged simultaneously in all 9 compartments. For the first time at ILVO, the color and intensity of lighting can be varied in this building. For drinking water, each compartment has 3 pipes (rain water, ground/well water and tap water). Grates can be placed under the chickens to test fecal matter, for example.

Gaining and sharing knowledge

"This building opens perspectives to further develop both our fundamental and application-oriented specialized knowledge and to share it with policy, industry and society," believes Evelyne Delezie, Poultry Research Coordinator at ILVO.

The tests and research in the new building may cover feeding, water, management strategies and their impact on animal behavior, animal health, emissions, excretions and meat quality. ILVO receives many questions about this from the sector. Optimal feed composition, feed requirements, valorization alternative additives or raw materials (e.g. algae, microbial protein or circular waste streams) are addressed in this independent knowledge center.

Testing with digital and robotic systems is certainly possible. Emissions will also be able to be measured end-of-pipe from now on. Correlating the sensors and automatic data collection from the central control to environmental and climate effects and to certain practices is among the possibilities.Winter garden and free range

In addition to the 9 fully enclosed compartments, there are 4 more compartments with additional daylight and a winter garden, with access to a free range. Research into alternative housing concepts and into organically raised or slow-growing chickens is thus an option. The compartments with a winter garden have a fixed roof and a windbreak net. In the event of an outbreak of bird flu, the free-range zone can easily be closed off from the winter gardens.

According to ILVO, the building can be considered a proof of concept, where both animal- and environment-related research can be conducted with the latest techniques and in collaboration with various research and/or private partners.Filip Van der Linden

Bron: Landbouwleven